| Research Article | ||

Open Vet. J.. 2025; 15(3): 1331-1339 Open Veterinary Journal, (2025), Vol. 15(3): 1331-1339 Research Article Eco-friendly dehairing of goat leather using indigenous rumen microorganisms: Physicochemical and sensory evaluationsDeni Novia1*, Afriani Sandra1, Riesi Sriagtula2, Hijratul Khairi Rambe1, Busmantoni Busmantoni1, and Aronal Arief Putra11Department of Animal Products Technology, Faculty of Animal Science, Universitas Andalas, Padang, Indonesia 2Department of Animal Nutrition, Faculty of Animal Science, Universitas Andalas, Padang, Indonesia *Corresponding Author: Deni Novia. Department of Animal Products Technology, Faculty of Animal Science, Universitas Andalas, Indonesia. Email: dnovia [at] ansci.unand.ac.id Submitted: 14/12/2024 Accepted: 17/02/2025 Published: 31/03/2025 © 2025 Open Veterinary Journal

AbstractBackground: The tanning industry is burdened with substantial environmental concerns, especially due to hazardous chemicals used in dehairing and chrome tanning processes. This research investigates the application of indigenous microorganisms (IMO) derived from rumen fluid, integrated with gambier-based vegetable tanning, to create an eco-friendly dehairing method for goat hides while examining its effects on their physicochemical and sensory characteristics. Aim: Dehairing goat leather using enzymes from IMO of rumen fluid is an environmentally friendly alternative. This study evaluated the impact of rumen liquid IMO on the dehairing process of gambier goat leather and its physicochemical and sensory properties. Methods: This study used 20 pieces of goat leather and rumen liquid. This study used an experimental method with a completely randomized design, five treatments, and four replications. The treatments included soaking the skin in rumen liquid IMO for 0–4 days and adding 6% lime. Results: The results showed that the use of rumen fluid IMO in the dehairing process significantly affected (p < 0.05) the tensile strength, elongation, rawhide substance, degree of tanning, water-soluble substances, and sensory value. Nonetheless, they exerted no substantial impact (p > 0.05) on Zwik strength, moisture, fat, bound tannin, and ash content. Conclusion: The best treatment in terms of physicochemical and sensory properties on goat skin is soaking for three days in rumen fluid IMO, with the following characteristics: the meat part is clean from meat residue, the skin condition is quite soft, the skin color is yellowish brown, and the skin surface is smooth, where the test meets the SNI quality standards of 06-0463-1989. Keywords: Dehairing, Gambier tanning, Goat leather, Physicochemical, Rumen liquid IMO. IntroductionThe development of goat farming in Indonesia offers an opportunity for leather management. Based on the data issued by BPS Indonesia, the population of goats in West Sumatra in 2022 was 242,302, while in Indonesia, the overall population was 18,560,835 (BPS, 2024). Goat skin is a type of skin that is suitable for tanning leather. The tanning industry has long been known to contribute significantly to environmental pollution, especially in the chrome tanning and dehairing processes, which generally use hazardous chemicals (Chiampo et al., 2023). Using these chemicals not only endangers the environment but also the health of workers. Therefore, developing environmentally friendly tanned leather is needed, starting with gambier-based tanning materials. In addition, more environmentally friendly dehairing methods are the main focus in developing a sustainable leather tanning industry (de Castro Bizerra et al., 2024). The gambier extract is derived from the gambier plant (Uncaria gambier Roxb) and includes tannin components suitable for vegetable tanning. Gambier has excellent potential as a vegetable tanning material (Juliyarsi et al., 2013; Kasim et al., 2013). The tannin components in gambier rapidly interact with skin proteins, yielding tanning results appropriate for use as fundamental materials in belts and bags, particularly those crafted by hand. One promising approach is the use of microorganism-produced proteases. Several recent studies have shown the potential of using proteases in environmentally friendly dehairing processes. Khan et al. (2023) evaluated protease production by Bacillus subtilis ZMS-2 and its application in the tanning industry. Akhtar et al. (2024) demonstrated the effectiveness of Bacillus species proteases for environmentally friendly cowhide dehairing processes. Indigenous microorganisms (IMO) in rumen fluid have attracted attention as potential sources of protease enzymes for dehairing. Producing and optimizing bacterial and fungal proteases for dehairing animal hides is a sustainable development in leather manufacturing (Ugbede et al., 2023). Furthermore, Liya et al., (2023) demonstrated the potential of keratinolytic protease from Bacillus tropicus LS27 as a sustainable alternative for dehairing. The study by Ramadhan and Novia (2024) required 24 h to dehair dry salt-cured cowhide using elephant grass IMO and 6% lime. Although many studies have been conducted on using protease enzymes in the dehairing process, rumen fluid as a source of protease enzymes for the dehairing process of goat hides has yet to be explored. In addition, the effect of the duration of soaking the hide in rumen fluid IMO on the physicochemical and sensory qualities of gambier-tanned goat hides has not been previously reported. This study combined rumen fluid IMO with 6% lime for dehairing, a new approach to optimizing the environmentally friendly leather tanning process. This study aimed to determine the effect of soaking in rumen fluid IMO during dehairing on gambier-tanned goat leather’s physicochemical and sensory properties. Materials and MethodsMaterials researchThe study utilized 20 sheets of salt-preserved goat skin purchased from Padang City, 10 kg of gambier powder obtained from gambier farmers in Limapuluh Kota Regency, and rumen fluid obtained from a slaughterhouse in Padang City, Indonesia.

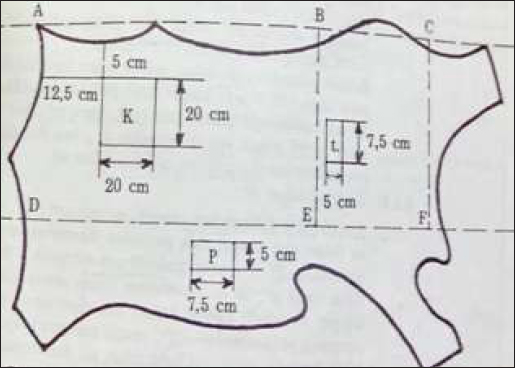

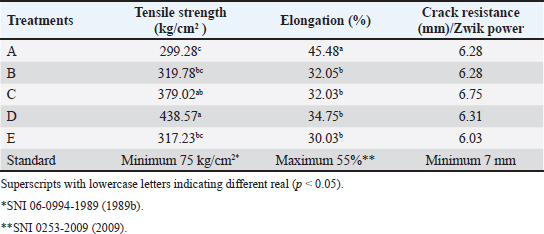

Fig. 1. Place retrieval example test (SNI 06-0463-1989) (1989a). In this case, the chemical materials used are H2SO4 (concentrated sulfuric acid) 1.5%, NaCl 10%, Za 0.5%, teepol (soap) 1%, or open 0.5%, FA (formic acid) 1%, Na2S 2%, n atrial bicarbonate 2.5%, sodium carbonate (Na2CO3) 0.5%, Ca(OH)2 (quicklime) 6%, anti-fungal (preventol) 0.02%, and water 1280%. Rumen fluid, granulated sugar, and coconut water. The percentage was calculated by skin weight. Furthermore, the equipment used includes tanning drums, scales, pH meter, digital scales, knife stainless steel, basin, rope raffia, frame for stretching, tensile strength tester, lactometer, thickness gauge, caliper, glass measuring, ruler, pencil, scissors, board runway for throwing away meat, and scissors stainless steel. Design studyThis study used an experimental method with a completely randomized design consisting of five treatments and four replications. The treatment uses rumen fluid IMO as much as 33% from heavy skin with the immersion length: A=0 days (control), B=1 day, C=2 days, D=3 days, and E=4 days. The data were also analyzed using SPSS. Place retrieval example testThe place-taking example test is shown in Figure 1. Observed parametersThe parameters observed are the physicochemical and sensory of tanned leather. The physicochemical parameters were tensile strength test, elongation test, Zwik strength test, moisture content, oil/fat content, water-soluble substance content, rawhide content, insoluble ash content, bound tanning substances (tannins) content, and degree of tanning (SNI 06-0463-1989a). The leather was cut with a knife or scissors for chemical tests into small pieces measuring (5 x 5) mm2, as presented in Figure 1. The leather was then mixed evenly (homogeneous). The test sample was also used. Sensory value testing was conducted by spreading the leather on a table with the nerf part above, then observed with the five senses (SNI 0463-1989a), with several moderately trained panelists from 25 people. The serving was carried out by giving random samples to the panelists, who were not allowed to repeat the assessment or compare the samples presented. Then the panelists were asked to fill out a numeric scale form according to the scale given: meat section observed the remaining meat (1=meaty, 2=slightly meaty, 3=clean from meat), leather condition, observed by holding (1=stiff, 2=quite limp, 3=limp), nerf or rajah color (1=brownish yellow, 2=reddish brown, 3=brown), nerf or rajah section, held the nerf surface (1=rough, 2=slightly slippery, 3=slippery). Implementation studyThe process of removing tanned leather hair using rumen fluid (IMO) consists of the following stages: IMO fermentation includes fermented sugar, rumen fluid, and coconut water with a ratio of 1:2:10 for seven days in facultative anaerobes condition (G1); next is making second generation (G2), i.e., IMO liquid, coconut water, and sugar with a ratio of 1:5:0.5 for four days Tan goat leather includes soaking wet salt-preserved leather in a container with an amount of water ten times the weight of the leather; after, soaking the skin in IMO solution with a concentration of 33% and 6% quicklime, for zero until three days (appropriate treatment); throw away flesh and fur, neutralize skin, scraping protein and fat, pickling using H2SO4, adding anti-fungal, tanning leather with 25% gambier, washing the resulting skin with water, and drying the tanned leather with indirect sunlight. Table 1. Physical properties of gambier-tanned goat leather.

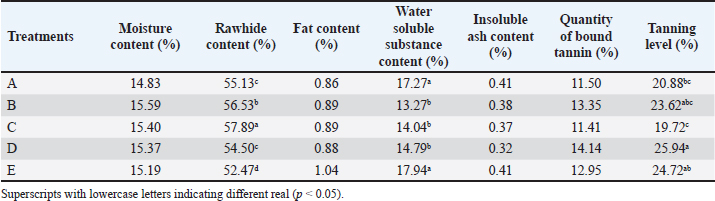

Ethical approvalThis study did not use animals directly; it only used dried salt-preserved goat skin, and the sensory analysis was only visual; therefore, there was no ethical approval. ResultsPhysical characteristics of gambier-tanned goat leatherThe analysis results for gambier-tanned goat leather demonstrate that the dehairing process using different immersion times in rumen fluid IMO affects the pulling strength and elongation. However, there was no influence on the cracking strength Table 1. The longer the soaking time, the gambier-tanned goat leather in the rumen fluid IMO solution increases the dragging strength and decreases the gambier-tanned goat leather elongation. Table 1 shows that the average tensile strength test with the treatments of adding IMO had the highest soaking time in treatment D (three days soaking), while the lowest tensile strength was found in treatment A (control). This standard is based on the SNI (1989b), with a minimum standard of 75 kg/cm2. The subsequent Duncan’s test analysis revealed that treatment A exhibited statistically significant differences compared with treatments C and D. However, no substantial disparities were observed between treatments A, B, and E. The average mark test revealed that the highest elongation of gambier-tanned goat leather was observed in treatment A (control). Meanwhile, the lowest tensile strength was observed in treatment E (4 days). Duncan’s test results showed that treatment A exhibited significant differences compared with treatments B, C, D, and E. Crack resistance (mm)/Zwik power with the addition of rumen fluid IMO against the old immersion range between 6.03 and 6.75 mm. Chemical characteristics of gambier-tanned goat leatherGambier-tanned goat leather shows its diverse influence on raw substance skin, grade substances late in water, and degree of tanning. However, no significant effect was observed, ash fat levels were not dissolved, and tannin was bound to Table 2. The average moisture content of vegetable tanning, with the addition of rumen fluid IMO, during the dehairing of goat leather was 14.83%–15.59%. The difference in the addition of IMO to the moisture content was influenced by the condition of the leather itself, where each treatment had the same ability to hydrolyze globular proteins, most of which were left only fiber proteins (collagen), where this collagen tissue did not bind much water. The average fat content of vegetable tanning with the addition of rumen fluid IMO during dehairing of goat skin was the highest in treatment E, 1.04%, and the lowest in treatment A, 0.86%. Water-soluble substance levels are a way to determine the amount of tannin that is not bound or filled too much with objects easily dissolved in water in the tanned leather. The highest levels of water-soluble substances were observed in treatment E, whereas the lowest levels were observed in treatment B. Duncan’s further test results showed that the levels of soluble substances in vegetable tanning water with gambier in treatment A (control) were significantly different from those in treatments B, C, and D but not significantly different from those in treatment E. The high levels of soluble substances in treatment E, with an average of 17.94%, were influenced by the duration of hide immersion in IMO-enriched rumen fluid during the depilation phase, causing the skin tissue structure to be more open but damaged by microbes so that the tanning agent that entered had not penetrated properly to form bonds with collagen fibers in goat skin so that some tannin content in gambier did not bind to the leather and dissolved into water. Gambier-tanned goat leather’s average insoluble ash content was 0.32%–0.41%. The average level of bound tannin in vegetable tanning with the addition of rumen fluid during dehairing was 11.41%–14.14%. The insignificant effect of the bound tannin level is due to the sum of the water, rawhide, fat, seawater, and insoluble ash levels, which were statistically the same. The tanning degree of gambier-tanned goat leather was 19.72%–25.94%. Duncan’s further test results showed that the degree of tanning in vegetable tanning with gambier treatment A (control) was not significantly different from treatments B, C, and E but was significantly different from treatment D. Table 2. Chemical properties of gambier-tanned goat leather.

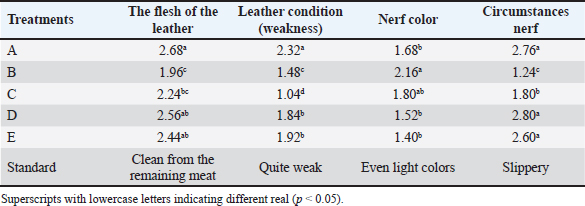

Table 3. Sensory values of gambier-tanned goat leather.

Sensory value of gambier-tanned goat leatherAnalysis results in diversity study gambier-tanned goat leather with prolonged soaking different in the dehairing process had an effect real to part flesh on the leather, condition (weakness), nerf color, and circumstances nerf, as seen in Table 3. The highest meat portion of gambier-tanned goat leather was in treatment A, with an average of 2.68 (clean from meat); the lowest average was in treatment B, with an average of 1.96 (slightly meaty). Subsequent analysis using Duncan’s multiple range test revealed that treatment A exhibited statistically significant differences from treatments B and C. However, no significant disparities were observed between treatments A, D, and E. Table 3 shows the average sensory values for leather conditions with the highest rumen fluid IMO material found in treatment A, with an average of 2.32 (relatively weak). The lowest average was observed for treatment C1.04 (rigid). Further test results showed that the treatment was different from the other treatments. This was caused by the laxity of the leather resulting from tanning, which affected the protein content in the leather, where the tanned leather became weak because of the reduction of leather proteins, except collagen, in the calcification process and scraping proteins (batting). The average nerf color sensory with the highest rumen fluid IMO ingredients was found in treatment B, with a mean of 2.16 (reddish brown). In contrast, the lowest average was found in treatment E, with an average of 1.40 (yellow-brownish) (Table 3). Subsequent analysis employing Duncan’s multiple range test demonstrated that treatment A exhibited statistically significant differences from treatment B. However, no significant differences were detected between treatments A and C, D, and E. The average circumstances of the nerf state with the highest rumen fluid IMO material found in treatment D was an average of 2.80 (slippery), and the average lowest was in treatment B, with an average of 1.24 (rough). The statistical analysis revealed that treatment A exhibited statistically significant differences from treatments B and C. However, no significant disparities were observed between treatments A, D, and E. DiscussionTensile strengthThe difference was that the addition of rumen fluid depends on the soaking time. Protease enzyme content influences the fluid rumen pulling strength test IMO. Proteases can loosen the hair structure by unplugging it until the roots are reached. Akhtar et al. (2024) showed that proteases from Bacillus species effectively loosen and remove hair on cow skin (Akhtar et al., 2024). This is further in line with the research conducted by Khan et al. (2023) that the protease produced by B. subtilis ZMS-2 is effective against skin dehairing. This enzyme hydrolyzes keratin protein in hair follicles, thereby loosening the hair structure and facilitating hair removal. The maximum tensile strength was observed in specimens subjected to treatment D (soaking rumen fluid IMO for three days), namely 438.57 kg/cm2. This was caused by the enzyme protease, which can remove hair from the roots to the skin’s surface to look clean, and a soaking time of 3 days is the optimal day for hair removal. The research results obtained by Liya et al. revealed that keratinolytic protease from B. tropicus LS27 could degrade the keratin structure in feathers, enabling effective hair removal without harmful chemicals (Liya et al., 2023). This result also aligns with earlier research by Akhtar et al. (2024), which found that complete hair removal, including hair roots, contributes to better penetration of tanning agents and produces leather with optimal strength. Research by Liya et al. (2023) showed that enzymes that effectively remove hair from the roots produce better-quality skin, including higher strength and high-quality tanned leather (Ugbede et al., 2023). The lowest tensile strength was achieved in treatment A (control without soaking) at 299.28 kg/cm2. This treatment was performed without IMO soaking but using Na2S to remove hair. The low tensile strength in this treatment was due to the discarded feathers not being pulled out, which got to the roots but were destroyed with the solution, resulting in a tanning agent that entered the leather more than the treatment. In line with the research by Zhang et al. (2024) on optimizing a neutral protease and MgCl2 system for continuous beam house processing, incomplete hair removal can result in uneven distribution of the tanning agent, affecting the strength and quality of the final hide. The tensile strength of rabbit skin tanned using gambier increases with the increasing concentration of gambier (Andini et al., 2023). Research by Ediari et al. (2002) found that hair removal with Rhizopus protease enzyme produces a tensile strength of 193.00 kg/cm2, and research by Fitriyanto et al.’s hair removal of sheep skin using 1% alkaline protease enzyme tanned with chrome has a tensile strength of 34.35 N/mm2 or 350.27 kg/cm2 (Fitriyanto et al., 2021), but is still relatively low compared to the research by Kasim and Mutiar (2016) tensile strength with combination tanning, namely gambier and KAI(SO4)2, produces a figure of 990.71 kg/cm2. The presence of enzyme inhibitors affects the decrease in the tensile strength of E treatment in the reaction environment, which can reduce the effectiveness of the enzyme in the hair removal process (Zhang et al., 2024). ElongationThe high elongation aligns with the previous research conducted by Ardinal and Samaria (2023), which showed that increasing the concentration of gambier tanning material processing wastewater for tannery with variations of alum and tuning will reduce the resulting elongation. The different elongation of leather with the addition of IMO was due to the composition of protease enzyme in the IMO. Enzymes can waste proteins that remain in the leather; thus, leather elongation increases due to reduced protein content. The longer the immersion time enzymes used in the process of bating can cause the moisture content in the leather to decrease; in addition to protein, fat also hydrolyzes the process, liming and delimiting, which causes the leather to become hollower so that water will occupy the cavity (Faidha et al., 2014). The highest elongation was observed in treatment A (control without immersion). Elongation is closely related to leather laxity. When the leather is stretched, it becomes weak and not rigid. Leather elongation is related to the enervation or elasticity of the leather, which is produced when the leather becomes weak because of the reduction of elastin during the erosion of proteins in the leather (bating) (Suparno and Eko, 2012). The lowest elongation was observed in treatment E (immersion for four days), at 30.03%. However, the tanning agent did not affect elongation; it remained fat, which led to the influence of leather on elongation. This occurred because the existing fat and protein levels were not wholly eroded, thereby reducing the elongation of the leather. The more comprehensive angle of interwoven bundles of collagen fibers, thicker corium, and higher fat content, the lower the tensile strength and the higher the elongation (Feniya et al., 2015). Leather in the study: It was straightforward to throw away hair because long immersion time affects the process. In hairs, the skin was not upright and firm but slanted and not tight, indicating that protein keratin had been hydrolyzed and wasted from the skin. If the leather protein fibers are upright and tight, the leather will have low elongation, but if the leather fibers are located vertically and the weave is not tight, it stretches tall (Ibrahim et al., 2005). Results of this elongation were also classified as low compared with those of other studies, although with different treatments. The elongation test reached 68% with the addition of mimosa (Sutyasmi et al., 2016). The stretchability of the research results meets SNI standard No. 0463-1989a leather goat tanned with a maximum elongation standard of 25%. In this case, the highest elongation of dehair sheep leather was observed after treatment with 1.5% alkaline protease enzyme (34.92%) (Fitriyanto et al., 2021). Crack resistance (mm)/Zwik powerThe Zwik power with the addition of IMO was caused by the levels of protein and fat in the tanned leather. The meat remnants on the skin are tan with lower marks and test leather. The rate of proteins left behind on the skin’s surface makes the skin surface/nerf easily broken. According to SNI 06-0994-1989b, Zwik power is the ability of the leather to stretch to a certain height due to the force applied to its part of the flesh until the tattoo begins to crack. At optimal, the leather collagen and hydroxyl tannin groups are bonded cross with the strength to improve the Zwik endurance of the leather. Moisture contentThe value of the leather moisture content was also influenced by the penetration properties (penetration power) of the tanning agent in the leather, where the tanning agent content began to diffuse (spread) into the tanned area, adhere to the fibers, and release water (Novia, 2009). The results of the moisture content test in this study were lower than those of Juliyarsi et al. (2013), who also used gambier at a concentration of 25%, producing a moisture content of 17.06% and meeting the requirements of SNI 06-0463-1989, where the maximum percentage limit for moisture content according to SNI (1989a) is 18%. Rawhide substanceRawhide is a protein found in tanned leather with a tanning agent content. Based on Table 2, the average content of vegetable-tanned rawhide, with the addition of rumen fluid IMO, in the dehairing process on goat skin was highest in treatment C (average: 57.89%) and lowest in treatment E (average: 52.47%. Duncan’s test showed that the content of vegetable-tanned rawhide with gambier in treatment A (control) was significantly different from that in treatments B, C, and E but not significantly different from that in treatment D. The protease enzyme content influenced the high rawhide content in treatment C in rumen fluid. In my opinion, protease could erode protein to pull hair to the roots, but in treatment C, the development of protease was not optimal. The influence of this enzyme caused the skin tissue structure to be less open, thus affecting the ability of the tanning agent in gambier to penetrate and bind to skin collagen. The tanning compounds in gambier extract exhibit rapid reactivity with collagen fibers, making this material a specialized tanning agent for leather processing and its combination with leather proteins (Kasim, 2011). The lowest levels of rawhide substances in this E treatment were due to the length of soaking with rumen fluid IMO during the enhanced enzymatic activity during the dehairing process, which facilitates optimal hydrolysis of noncollagenous proteins, particularly globular proteins. This action leads to increased porosity of the skin tissue structure, thereby promoting more efficient penetration and interaction between tanning agents and the hide. Consequently, this process reduces the amount of rawhide. Syafie et al. (2013) posited that high protease activity enables a more effective hydrolysis of noncollagenous proteins, enhancing the openness of the skin’s structural matrix. This structural modification improves the penetration and interaction between the tanning compounds and the leather substrate. Fat contentThe difference in the fat content of gambier-tanned goat leather was due to the soaking in rumen fluid, which is influenced by the degreasing process before tanning (beam house). In this process, the actions taken were the same for each treatment, so the results were relatively the same. According to Ibrahim et al., teepol is added as an auxiliary material to remove fat, emulsifying it so it is easy to dissolve (Ibrahim et al., 2005). Water-soluble substance levelsThe lowest levels of dissolved substances in water were observed in treatment B (average: 13.27%. Low levels of dissolved substances are influenced by the length of soaking so that the enzymes can work optimally. The increased porosity of the dermal matrix facilitates enhanced penetration and efficient binding of tanning agents with the hidden substrate and between tanning materials. Enzymes require a long time to work optimally (Khan et al., 2023). Insoluble ash contentThe results of Novia’s research on insoluble ash are the remains of combustion from tanned leather and water-soluble substances in the ash content. Insoluble ash contains inorganic elements that cannot dissolve in water (Novia, 2009). Quantity of bound tanninThe level of bound tannin is the remaining component from the reduction of water, oil, water-soluble substances, insoluble ash, and rawhide components contained in tanned leather (Novia, 2009). The level of bound tannin was also influenced by the level of tanning substances that bind to the structure of the leather’s collagen tissue; the better the structure of the leather to be tanned, the higher the ability of tannin to bind, and vice versa, the worse the structure of the leather tissue produced, the lower the tannin would bind. The opening of the skin tissue structure is influenced by enzymes that work in the soaking process with rumen fluid IMO, resulting in a different skin structure. According to Akhtar et al. (2024), perfect hair removal contributes to better penetration of tanning agents, increasing the penetration of tanned leather and bound tanning agents. Tanning levelThe high degree of tanning in treatment D was due to the prolonged soaking of the skin with the addition of rumen fluid IMO in the dehairing process, which increased the penetration of tanning agents, more effective hair removal, preservation of collagen structure, and modification of the leather surface. This occurs because enzymes remove hair and open the collagen fiber structure, allowing tanning agents to penetrate deeper and more evenly (Andini et al., 2023). Enzymes can clean the skin of noncollagen proteins and cell debris more effectively than conventional chemical methods. This process creates more reactive sites on collagen to interact with tanning agents, thereby increasing the degree of tanning (Akhtar et al., 2024). Enzymatic methods tend to be less sensitive to collagen structures than chemical methods. Better preservation of collagen structure allows for more optimal interaction between collagen and tanning agents (Liya et al., 2023). Enzymes can modify the leather surface in a way that favors tanning. This modification can create better conditions for tanning agent binding, thus increasing the degree of tanning (Biškauskaite et al., 2024). In line with the research of Kasim et al., it was found that the tanning degree of gambier-tanned goat leather is 26.86% (Kasim et al., 2013) while tanning using 1% chromium and 8% gambier resulted in a tanning degree of 24.08 ± 0.09 and the more chromium added, the higher the tanning degree (Kasim et al., 2014). The meat portion of the tanned leatherThe concentration of rumen fluid was significantly different from the cleanliness of the flesh on tanned leather because it affected the cleanliness of the leather by removing meat and bating. These two processes were performed in the same manner in all the treatments. Dehairing the skin using the G3726 enzyme selectively removes hair, only targeting the proteins that bind hair to the skin, thereby making the skin cleaner and more environmentally friendly (Li et al., 2022). According to Tika et al. (2016), since meat is still thrown away manually using a butcher knife, the thickness of the leather is not obtained evenly. Leather condition (leather weakness)Enzymes are essential for addressing skin weakness and skin elasticity. The high average skin elasticity was attributed to removing residual meat and fat during the dressing process. The lower meat and fat content will result in high elongation, weakening the skin. The work of enzymes in assisting the hair removal process also helps with tanning. If it needs to be improved, the dressing process can prevent the skin from becoming hard and breaking easily (Zhang et al., 2021). In enzymatic hair removal using enzymes from Subtilisin Carlsberg, the resulting skin surface is softer and smoother than that obtained by chemical methods (Eser et al., 2022). Nerf colorSensory evaluation of the grain surface revealed predominant brown and yellow hues. Ugbede et al. explained that remaining hair can interfere with tanning, affecting the final leather’s visual aspects, including color. This is in line with leather, which results from tanning with a gambier color that is yellow and evenly browned (Novia, 2009). Enzymatically dehaired goat skin produced by B. subtilis SCK6 exhibited better general appearance and whiteness in visual tests (Tian et al., 2019). Circumstances nerfThis occurs because when the hair is removed, the hair contained in the hair surface is uprooted. Although it is not too clean, the surface leather felt clean, and the addition of the tanning agent was provided. Biškauskaitė et al. emphasized the importance of an effective dehairing process to produce high-quality leather so that incomplete hair removal can affect the final quality of the leather (Biškauskaite et al., 2024). The tannins found in tanning agents bind with fellow tannins in the tanning process and fill a room empty between the collagen chains to affect the state of the nerves. Gambier integrates with leather proteins to produce soft, delicious tanning results that are touched and fine (Kasim, 2011). ConclusionIMO from rumen fluid were used as an environmentally friendly method for dehairing gambier-tanned goat leather. Soaking the skin in rumen fluid IMO for three days gave the best results, significantly affected the physicochemical and sensory properties of the leather, and produced leather quality that met the SNI 06-0463-1989 standard. This method is a more environmentally friendly alternative to traditional hair removal methods, potentially reducing the negative impact of the tanning industry on the environment. Further optimization of the soaking time and concentration of IMO, a comparison between this method and traditional efficiency and environmental impact techniques, and its application on an industrial scale and other types of leather are necessary. Research on the use of rumen fluid IMO is still based on the general protease content. Further research should focus more on using alkaline protease (keratinase) from IMO, which is more effective for hair removal. AcknowledgmentThe authors would like to express gratitude to the Directorate of Research and Technology, under the auspices of the Ministry of Education, Culture, Research, and Technology, which funded this research, then to LPPM and Animal Science Faculty, Universitas Andalas for supporting this research, and to Research Laboratory members who provided technical assistance in conducting this research. Conflict of interestThe authors declare no conflict of interest. FundingThis work was supported by Universitas Andalas (Fundamental Research grant no. 041/E5/PG.02.00.PL/2024. Authors’ contributionDN: conceptualization, project administration, methodology, data curation, visualization, writing, and investigation. AS: conceptualization, methodology, data curation, writing. AAP: data curation and visualization. RS: data curation and visualization. HKR: methodology, data curation, investigation, and data visualization. B: methodology, data curation, and investigation. Data availabilityAll data are presented in this article. ReferencesAkhtar, M.A., Butt, M.Q.S., Afroz, A., Rasul, F., Irfan, M., Sajjad, M. and Zeeshan, N. 2024. Approach towards sustainable leather: characterization and practical industrial application of proteases from Bacillus sp. for ecofriendly dehairing of the leather hide. Int. J. Biol. Macromol. 266, 131154. Andini, R.A., Pertiwiningrum, A. and Abidin, M.Z. 2023. The use of gambier as a tanner for fur-tanned rabbit skin. BIO Web Conf. 81, 00012. Ardinal and Salmariza, S. 2023. The effect of the utilization of gambier processing wastewater for tannery with variations of alum and tunjung on the physical properties of the tannery physical properties test. J. Phys. Conf. Ser. 1–6. Available via iopscience.iop.org Biškauskaite, R., Lee, W.C. and Valeika, V. 2024. Crude proteolytic enzyme from B. halodurans BCRC 910501 and its application in leather processing. Heliyon 10(16), e35842. BPS (Badan Pusat Statistik) Indonesia. 2024. Goat population by Province (head), Jakarta, Indonesia: Badan Pusat Statistik. 2021-2023. Chiampo, F., Shanthakumar, S., Ricky, R. and Ganapathy, G.P. 2023. Tannery: environmental impacts and sustainable technologies. In Materials today: proceedings. Elsiviier, Amsterdam, Netherlans. de Castro Bizerra, V., Sales, M.B., Melo, R.L.F., do Nascimento, J.G.A., Brandão Junior, J., Silva, M.P.F., dos Santos, K.M., da Silva Sousa, P., da Fonseca, A.M., de Souza, M.C.M. and dos Santos, J.C.S. 2024. Opportunities for cleaner leather processing based on protease enzyme: current evidence from an advanced bibliometric analysis. Renew. Sustain. Energy Rev. 191, 114162. Ediari, P., Widowati, T.P., Mustofa, H., Supriyono, T.C.B. and Susila, R.J. 2002. Penerapan Protease Rhyzopus sp. pada proses buang bulu ramah lingkungan. In Prosiding seminar Nasional II Industri Kulit, Karet dan Plastik. Eds., Balai Besar Penelitian dan Pengembangan Industri Barang Kulit, Karet dan Plastik. Yogyakarta, Indonesia: Balai Besar Penelitian dan Pengembangan Industri Barang Kulit, Karet dan Plastik, pp: 5. Eser, A. and Aydemir, T. 2022. Subtilisin Carlsberg immobilization and its application for ecofriendly leather processing. J. Clean Prod. 377, 134296. Faidha, S., Putut, H.R. and Anggo, A.D. 2014. The effect of long soaking with papain enzyme on bating process to quality of tanned tilapia (Oreochromis niloticus) skin. J. Pengolahan Bioteknol. Hasil Perikan. 4(1), 15–20. Feniya, Z., Fronthea, S. and Ima, W. 2015. The effect of soga tingi (Ceriops tagal) utilization as a tanning material on the quality of physical and chemical milkfish skin (Chanos chanos Forsk). J. Pengolahan Bioteknol. Hasil Perikan. 5(1), 112–117. Fitriyanto, N.A., Musthofiyah, Muhlisin, Pertiwiningrum, A., Kurniawati, N., Prasetyo, R.A., Azkarahman, A.R. and Erwanto, Y. 2021. Enzymatic activity of alkaline protease from Bacillus cereus TD5B and its application as a sheep skin dehairing agent. Leather and Footwear J. 21(2), 105–118. Ibrahim, L., Juliyarsi, I. and Melia, S. 2005. Ilmu dan teknologi pengolahan kulit. Padang, Indonesia: Fakultas Peternakan Unand. Juliyarsi, I., Novia, D. and Helson, J. 2013. Study of gambier addition as vegetable tanner materials to chemical quality goat leather. J. Peternak Indones. 15(1), 35–45. Kasim, A. 2011. Proses produksi dan industri hilir gambier. Jakarta, Indonesia: Universitas Andalas Press. Kasim, A. and Mutiar, S. 2016. Goatskin tanning for obtaining high tensile strength leather by using tanning combination. In: Prosiding seminar nasional kulit, karet dan plastik ke-5. Yogyakarta, Indonesia: Balai Besar Kulit, Karet dan Plastik (BBKKP). pp: 1–12. Kasim, A., Novia, D., Mutiar, S. and Pinem, J. 2013. Characterization of goat skin on the preparation of leather tanned with gambier and properties of leather. Maj. Kulit Karet Plast. 29(1), 1–12. Kasim, A, Novia, D, Mutiar, S. 2014. Diminishing chromium use on combined chromium-gambier tanning process upon the characteristics of tanned leather. Med. Peternak. 37(1), 24–29. Khan, Z., Shafique, M., Jabeen, N., Naz, S.A., Yasmeen, K., Ejaz, U. and Sohail, M. 2023. Protease from Bacillus subtilis ZMS-2: evaluation of production dynamics through Response Surface Methodology and application in leather tannery. J. King Saud. Univ. Sci. 35(4), 102643. Li, X., Zhang, S., Zhang, Q., Gan, L., Jiang, G., Tian, Y. and Shi, B. 2022. Characterization and application of a novel halotolerant protease with no collagenase activity for cleaner dehairing of goatskin. Process Biochem. 113, 203–215. Liya, S.M., Umesh, M., Nag, A., Chinnathambi, A., Alharbi, S.A., Jhanani, G.K., Shanmugam, S. and Brindhadevi, K. 2023. Optimized production of keratinolytic proteases from Bacillus tropicus LS27 and its application as a sustainable alternative for dehairing, destaining, and metal recovery. Environ. Res. 221, 115283. Novia, D. 2009. Pengaruh perlakuan awal daun/ranting tanaman gambier (Uncaria gambier Roxb) terhadap kadar tannin ekstrak yang dihasilkan dan kemampuan penyamakannya pada kulit kambing. J. Peternakan 6(1), 22–28. Ramadhan, AM. and Novia, D. 2024. Innovative raw material for crackers: dehairing durable dry salt-cured skin with elephant grass IMO. Andalasian Livestock 1(1), 1–8. Standar Nasional Indonesia (SNI). 1989a. SNI. 06-0463-1989. Kulit lapis domba/kambing samak kombinasi (krom nabati). Jakarta, Indonesia: Badan Standarisasi Nasional (BSN). Standar Nasional Indonesia (SNI). 1989b. SNI. 06-0994-1989. Uji derajat penyamakan (DP) kulit samak. Dewan Standarisasi Nasional. Jakarta, Indonesia: Badan Standarisasi Nasional (BSN). Standar Nasional Indonesia (SNI). 2009. SNI. 0253-2009. Kulit bagian atas alas kaki-kulit kambing. Dewan Standarisasi Nasional. Indonesia. Suparno, O. and Eko, W. 2012. The effects of sodium percarbonate concentration and amount of water in the chamois tanning on the chamois leather quality. J. Tek. Ind. Pertan. 22(1), 1–9. Sutyasmi, S., Titik, P.W. and Noor, M.S. 2016. The effect of mimosa on the tanning of vegetable-tanned sheep leather for jackets using C-RFP system on the organoleptic, physical, and morphology properties of leather. Maj. Kulit Karet Plast. 32(1), 31–38. Syafie, Y., Triatmojo, S. and Pertiwiningrum, A. 2013. The utilization of Aspergillus sp. and Rhizopus sp. protease at different concentrations in the unhairing phase of tanning on the physical quality of sheep leather and liquid waste. Bul. Peternak. 37(3), 198–206. Tian, J., Xu, Z., Long, X., Tian, Y. and Shi, B. 2019. High expression of keratinase by Bacillus subtilis SCK6 for the enzymatic dehairing of goatskins. Int. J. Biol. Macromol. 135, 119–126. Tika, K., Ratna, I. and Putut, H.R. 2016. The effect of different tanning materials towards leather quality of tanned mondol stingray (Himantura gerrardi). Indones. J. Fish Sci. Technol. 11(2), 140–147. Ugbede, A.S., Abioye, O.P., Aransiola, S.A., Oyewole, O.A., Maddela, N.R. and Prasad, R. 2023. Production, optimization partial purification of bacterial and fungal proteases for animal skin dehairing: a sustainable development in leather-making process. Bioresour. Technol. Rep. 24, 101632. Zhang, M., Tang, C., Liu, J., Qin, S., Kaya, M.G.A. and Tang, K. 2024. Optimization of MgCl2-assisted neutral protease system for sustainable beamhouse processing. Biochem Eng J. 207, 109331. Zhang, Y., Liu, H., Tang, K., Liu, J. and Li, X. 2021. Effect of different ions in assisting protease to open the collagen fiber bundles in leather making. J. Clean Prod. 293, 1–10. | ||

| How to Cite this Article |

| Pubmed Style Novia D, Sandra A, Sriagtula R, Rambe HK, Busmantoni B, Putra AA. Eco-friendly dehairing of goat leather using indigenous rumen microorganisms: Physicochemical and sensory evaluations. Open Vet. J.. 2025; 15(3): 1331-1339. doi:10.5455/OVJ.2025.v15.i3.24 Web Style Novia D, Sandra A, Sriagtula R, Rambe HK, Busmantoni B, Putra AA. Eco-friendly dehairing of goat leather using indigenous rumen microorganisms: Physicochemical and sensory evaluations. https://www.openveterinaryjournal.com/?mno=211509 [Access: January 25, 2026]. doi:10.5455/OVJ.2025.v15.i3.24 AMA (American Medical Association) Style Novia D, Sandra A, Sriagtula R, Rambe HK, Busmantoni B, Putra AA. Eco-friendly dehairing of goat leather using indigenous rumen microorganisms: Physicochemical and sensory evaluations. Open Vet. J.. 2025; 15(3): 1331-1339. doi:10.5455/OVJ.2025.v15.i3.24 Vancouver/ICMJE Style Novia D, Sandra A, Sriagtula R, Rambe HK, Busmantoni B, Putra AA. Eco-friendly dehairing of goat leather using indigenous rumen microorganisms: Physicochemical and sensory evaluations. Open Vet. J.. (2025), [cited January 25, 2026]; 15(3): 1331-1339. doi:10.5455/OVJ.2025.v15.i3.24 Harvard Style Novia, D., Sandra, . A., Sriagtula, . R., Rambe, . H. K., Busmantoni, . B. & Putra, . A. A. (2025) Eco-friendly dehairing of goat leather using indigenous rumen microorganisms: Physicochemical and sensory evaluations. Open Vet. J., 15 (3), 1331-1339. doi:10.5455/OVJ.2025.v15.i3.24 Turabian Style Novia, Deni, Afriani Sandra, Riesi Sriagtula, Hijratul Khairi Rambe, Busmantoni Busmantoni, and Aronal Arief Putra. 2025. Eco-friendly dehairing of goat leather using indigenous rumen microorganisms: Physicochemical and sensory evaluations. Open Veterinary Journal, 15 (3), 1331-1339. doi:10.5455/OVJ.2025.v15.i3.24 Chicago Style Novia, Deni, Afriani Sandra, Riesi Sriagtula, Hijratul Khairi Rambe, Busmantoni Busmantoni, and Aronal Arief Putra. "Eco-friendly dehairing of goat leather using indigenous rumen microorganisms: Physicochemical and sensory evaluations." Open Veterinary Journal 15 (2025), 1331-1339. doi:10.5455/OVJ.2025.v15.i3.24 MLA (The Modern Language Association) Style Novia, Deni, Afriani Sandra, Riesi Sriagtula, Hijratul Khairi Rambe, Busmantoni Busmantoni, and Aronal Arief Putra. "Eco-friendly dehairing of goat leather using indigenous rumen microorganisms: Physicochemical and sensory evaluations." Open Veterinary Journal 15.3 (2025), 1331-1339. Print. doi:10.5455/OVJ.2025.v15.i3.24 APA (American Psychological Association) Style Novia, D., Sandra, . A., Sriagtula, . R., Rambe, . H. K., Busmantoni, . B. & Putra, . A. A. (2025) Eco-friendly dehairing of goat leather using indigenous rumen microorganisms: Physicochemical and sensory evaluations. Open Veterinary Journal, 15 (3), 1331-1339. doi:10.5455/OVJ.2025.v15.i3.24 |